California Senate Bill 673 (SB-673) went into effect on January 1, 2019, bringing enhanced regulations to hazardous waste facilities in the state. The new regulations were designed to incentivize facilities to reduce inspection violations, which in turn would result in better protection of public health and the environment over time, as well as protect worker safety and enhance financial assurance requirements to protect against changing economic conditions and inflation (Department of Toxic Substances Control [DTSC] Fact Sheet December 2018). Due to SB-673’s phased rollout plan, many hazardous waste facilities are just beginning to see its effects now in 2020.

What types of facilities are affected by SB-673?

The law applies to facilities that treat, store, transfer, dispose, and recycle hazardous waste as defined by California Code of Regulations, Title 22 (22 CCR) Section 66261.3. SB-673 affects hazardous waste facilities including commercial Resource Conservation and Recovery Act (RCRA) hazardous waste landfills, RCRA waste transfer stations, used oil handling and recycling facilities, federal laboratories, and federal military facilities. California’s unique inclusion of used oil in hazardous waste regulations has resulted in more businesses being impacted by the new law.

Tell me more about the phased rollout of SB-673

The rollout plan for SB-673 involves two tracks: Track 1, which went into effect January 1, 2019, focuses on five aspects of the hazardous waste permitting process, including increasing transparency in how a facility’s past violations factor into permitting decisions; expanding worker safety training; instituting stronger financial assurance rules; improving community involvement; and requiring further assessment to identify health risks from facility operations. Track 2, which has just begun to be implemented, establishes a framework to evaluate a hazardous waste facility’s cumulative impacts on the surrounding community. DTSC has been hosting public outreach events and generating these regulations since 2017.

Track 1: Hazardous Waste Facility

Track 1 involves five major components:

- Violation Scoring Procedure (VSP): Through this procedure, DTSC assigns facilities one of three compliance tiers based on violations from the preceding 10 years. DTSC then uses the compliance tiers to inform future permitting decisions. Preliminary VSP scores were issued to each permitted facility in late 2019 based on 22 CCR Section 66271.50 through 66271.57. VSP scores are updated annually and issued on September 30th. As of the 2019 VSP preliminary scoring, a total of 5 of the 79 hazardous waste permitted facilities in California received “Unacceptable” compliance tiers and 10 facilities received “Conditionally Acceptable” compliance tiers. Review of the 2019 VSP Score Matrix cards indicates a broad range of violations that resulted in high VSP scores, including improper hazardous waste storage locations, improper waste testing, improper drum rinsing, failure to document training, flaking epoxy coating on secondary containment, housekeeping, delays in notifying DTSC of a release of hazardous waste, and combining/storing incompatible wastes resulting in fires. Therefore, the VSP relies on DTSC facility inspections to determine whether the DTSC renews a facility permit. Making sure that facility inspections are carefully managed and violations quickly disputed will place more burden on the DTSC regulators, as well as the regulated community.

- Health Risk Assessment (HRA): Hazardous facilities must submit HRAs with their permit applications, increasing the amount of time needed to successfully complete the hazardous waste permitting process. The HRA determines how much risk, if any, a facility’s operations pose to the surrounding community through completion of an HRA Questionnaire, which includes an inventory of releases, emissions, and discharges.If constituents of concern are identified in air, surface water, soil, or groundwater associated with the site, the business will be required to evaluate potential receptors, transport processes, and exposure scenarios for each constituent along with a conceptual site model (CSM).

A more detailed Screening Level HRA may then be necessary to provide DTSC with additional HRA content for sites with evidence of onsite contamination, potential releases, potentially complete exposure pathways, or onsite receptors as described in 22 CCR 66270.14(e)(8)(B). Further, a comprehensive baseline HRA is required to be submitted for sites with offsite contamination, potential releases with consequences, potentially complete exposure pathway(s) or the risk of offsite receptors due to an upset at the facility. In addition, baseline HRAs are required for Class I hazardous waste landfills, treatment facilities with Title V air permits, hazardous waste incinerators, and boiler/furnaces that burn hazardous waste.

- Financial Assurance: Under the new regulations, more stringent financial requirements have been enacted to confirm a facility’s ability to clean up contaminated sites and conserve taxpayer funds (DTSC Financial Assurance Fact Sheet, December 2018). DTSC increased the minimum net worth of the company to $20 million as a financial test and corporate guarantee of a financial assurance mechanism. Only companies with credit ratings that meet new minimums (AAA, AA, A, or BBB as issued by Standard and Poor’s, or Aaa, Aa, A, or Baa as issued by Moody’s) are able to use financial test/corporate guarantees. Further, assets can only be relied on once and cannot be relied on for any other financial requirement imposed by the DTSC or another governmental agency. The new regulations also require submittal of a financial assurance mechanism within 90 days of DTSC’s approval of a corrective measures implementation work plan or equivalent.

Closure cost estimates under SB-673 must be prepared in accordance with ASTM E2150-17 Standard Classification for Life-Cycle Environmental Work Elements—Environmental Cost Element Structure. However, the ASTM guidance references RACER® cost estimating software, which is no longer sold commercially to industry. Therefore, it is up to the regulated community to prepare defensible closure cost estimates using engineer’s estimates and other commercial cost estimating software to meet the DTSC new regulatory requirements.

-

Training: Effective July 1, 2019, the employee training programs must be updated to include general awareness training and function-specific job training every two years [22 CCR Section 264.16(a)(4)]. An annual certification letter must be submitted by March 1st of each year effective March 1, 2021, and must include the job title for each position and the name of employee for each job as per 22 CCR 66264.16(f). This new regulation broadens the number of employees that require general awareness training on security and safety to include all personnel, even non-waste handling personnel.

-

Community Involvement Profiles: Facilities must include the DTSC Form 1195 Community Involvement Profile Form with their permit applications based on 22 CCR 66270.14(b)(23). The profile must include demographics, community interest, and the locations of sensitive receptors (e.g. schools, hospitals, etc.), nearby tribal lands, and other offsite sources of potential hazardous waste exposure.

Track 2: Vulnerable Communities and Cumulative Impacts

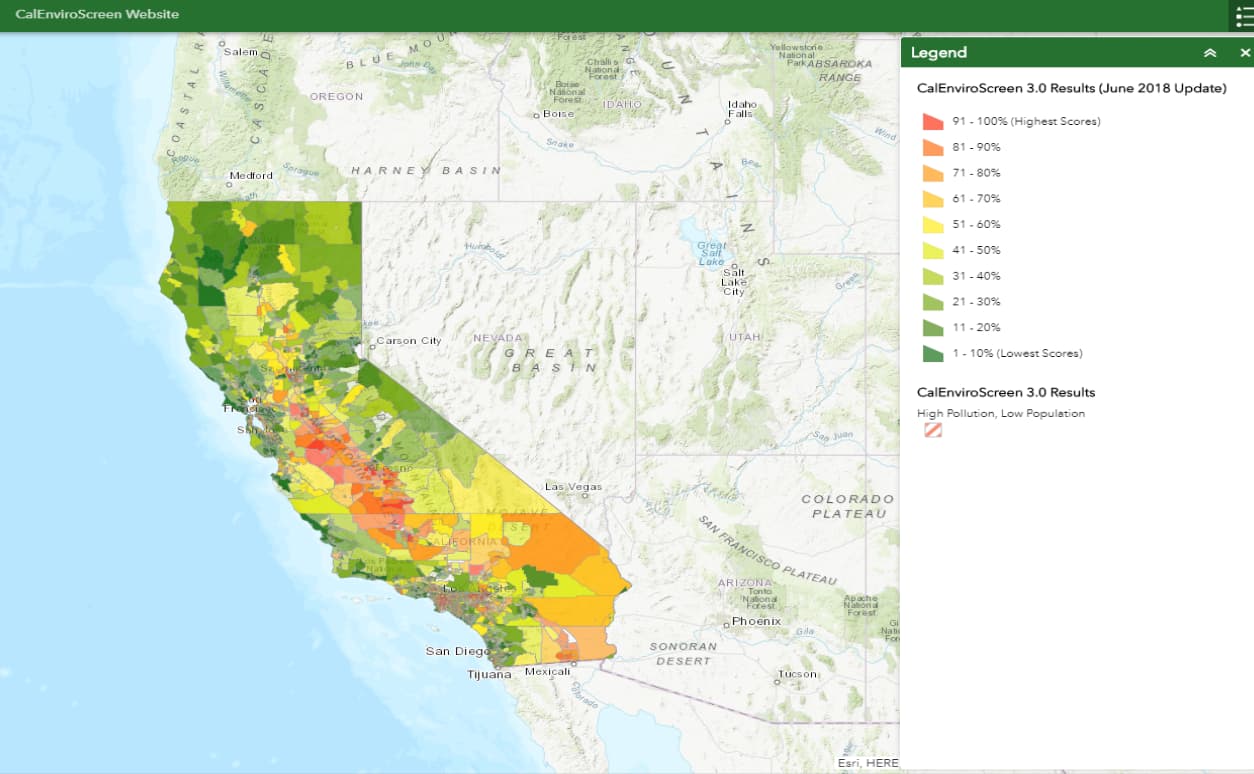

Track 2 directs the DTSC to consider “the vulnerability of, and existing health risks to, nearby populations” when deciding whether to issue permits or permit renewals to hazardous waste facilities. In California, nearly half of hazardous waste facilities are located within one-half mile of disadvantaged areas. As such, Track 2 also stipulates minimum set-back distances from community assets such as schools, daycare centers, and hospitals. The DTSC is using online tools, such as the CalEnviroScreen 3.0 released by the Office of Environmental Health Hazard Assessment (OEHHA), to score community pollution impacts and indicators of community sensitivity to pollution to assess community vulnerability. The CalEnviroScreen score considers numerous factors, including the “pollution burden” from regional air and water quality issues; the proximity to known cleanup sites, and area demographic factors such as health, education, employment, poverty, and linguistics. Since some facilities were present before the surrounding land use became residential, there are ongoing concerns from the regulated community with using the CalEnviroScreen model to issue California hazardous waste permits.

DTSC has also used the CalEEMod greenhouse gas (GHG) emissions evaluation tool to supplement the CalEnviroScreen model output. The CalEEMod evaluation involves submittal of basic information about facility truck trips, employee commute information, and construction details for expansion projects with the goal of encouraging less traffic and more efficient vehicle use.

What’s next?

Based on public comments submitted in April 2019, additional guidance from DTSC on the vulnerability evaluation process is likely forthcoming. Trihydro is currently compiling a statistical analysis of the 2019 VSP scores to identify lessons learned and assist the regulated community with staying in compliance with the new SB-673 requirements.

Want to learn more?

Contact us today to discuss compliance considerations.

Allison Riffel, P.E.

Engineering Specialist

(307) 745-7474

[email protected]