With aging water and wastewater systems experiencing growing demand, project teams are initiating a wave of infrastructure projects to address system challenges and improve system performance. As organizations plan new water and wastewater projects, we share five reasons 3D modeling should play a central role from project initiation through implementation.

1.) 3D models streamline project understanding

A tremendous amount of time and effort is spent getting team members and stakeholders on the same page during project planning. Identifying project drivers, outlining goals, and communicating anticipated challenges are all critical to developing a shared project understanding. Establishing the foundational context for upcoming project work can take numerous meetings with multiple project stakeholders.

Thanks to their highly visual nature, 3D models decrease the amount of time it takes for project stakeholders to develop a common project understanding. In essence, 3D models allow people to fast-forward through the project lifecycle and understand a project’s trajectory by beginning with a vision of the final product. A shared project understanding helps prompt discussions to confirm project objectives, and aids in the decision-making process.

3D modeling benefits also extend throughout a project’s lifecycle. Models can be managed and synced within cloud environments, allowing project stakeholders to view model updates as design decisions are made. Once construction is complete, the facility can use the 3D models to assist in plant operation, maintenance (e.g. tracking parts, flows through the plant, sample locations, repair locations, etc.), and safety planning (access routes, evacuation plans, etc.).

Above: The two 3D models shown above streamlined the project kickoff for a water treatment plant, allowing stakeholders to begin with a common understanding of the existing facilities and the proposed project deliverables.

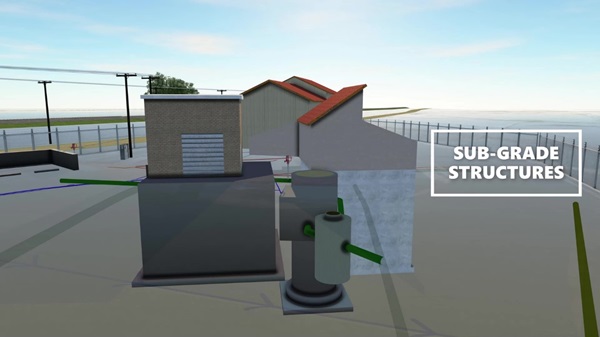

Above: This 3D model was used to evaluate potential below-grade structure and pipeline conflicts.

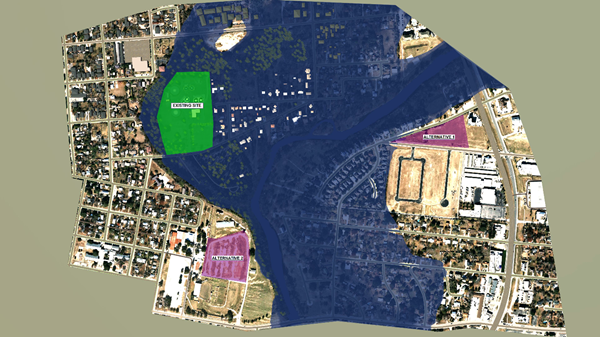

2.) 3D models simplify site layout evaluations

3D models can be especially helpful in the conceptual phase to make faster, more informed design decisions. The ability to visualize and manipulate various site configurations can reduce the overall amount of time spent on design because decision-makers can review available options, discuss pros and cons, and select the preferred path forward.

Above: Using the 3D model, project stakeholders were able to visually evaluate design alternatives at a water treatment facility.

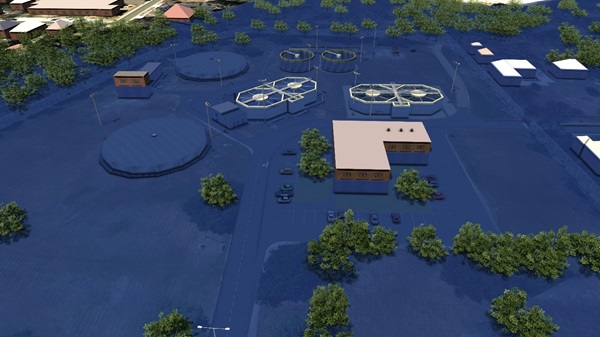

3.) 3D models aggregate stormwater information

Facilities often develop stormwater models and management plans to evaluate stormwater conveyance, storage, and discharge. Several storm events may be modeled and 3D models can facilitate a virtual walk-through of facility conditions with different storm scenarios. Information from the models may be used for specific design decisions, including:

- Understanding existing and proposed site locations relative to floodplains

- Modifying existing facility stormwater features to better protect the site during storm events

- Understanding how vegetation impacts stormwater conveyance and infiltration

- Designing stormwater ponds

Above: Stakeholders were able to visualize a permitted floodplain while prospecting new water treatment plant locations.

Above: A Texas water treatment plant leveraged 3D modeling to illustrate facility impacts during a 500-Year storm event.

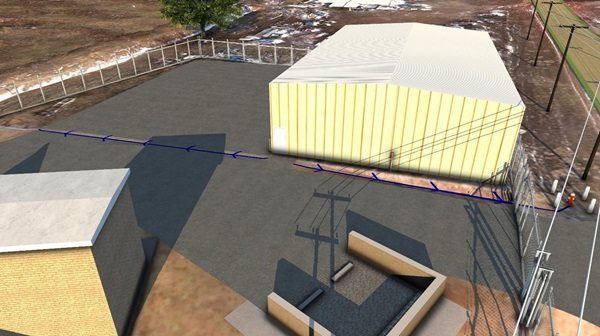

Above: A 3D model depicting the stormwater drainage away from a proposed metal building was created in early project stages to visualize plans for routing stormwater away from critical infrastructure.

4.) 3D models allow for subterranean visualization

3D modeling also illustrates our underground world via sub-surface models, which helps support project design and communication related to sub-surface utilities, building foundations, and soil profiles. With sub-surface models, project stakeholders can visualize underground assets and can confirm a given design is free of conflicts.

Above: A wastewater treatment plant in eastern Wyoming used a 3D model to align the proposed subsurface treatment plant system with the existing infrastructure.

5.) 3D models revolutionize project perspective

In water and wastewater projects, top priorities center around safety, cost-effectiveness, and system performance. However, aesthetics are a worthy consideration and 3D models provide design perspective to help bring aesthetic considerations to light. For example, 3D models may highlight a need to reduce the impact structures will have on sightlines and can assist in selecting materials that help facility components blend into the landscape.

Above: A water treatment plant in Texas used a 3D model to visualize different materials for their storage tanks. After viewing options via the below 3D model, stakeholders selected a material that reduced the plant’s visual impact on the surrounding community.

Above: A project in southeast Wyoming leveraged 3D models of proposed water tank configurations, allowing stakeholders to quickly see the visual impacts of tank configurations from familiar perspectives.

Interested in seeing 3D modeling in action at your site? Contact us!