Proposed Appendix K of the Environmental Protection Agency’s (EPA’s) proposed updates to New Source Performance Standards (NSPS) establishes optical gas imaging (OGI) survey procedure requirements. The proposed methodologies are wide-ranging, and would substantially impact the time and costs of conducting OGI surveys, similar to the other sections of Appendix K.

As proposed, Appendix K requires that each site have a monitoring plan describing the procedures for conducting a monitoring survey. This requirement is similar to what we have seen with previously written rules such as NSPS OOOOa. The monitoring plan must include:

- Procedures for daily verification checks

- Procedures to ensure monitoring is performed when field conditions are within established operating envelopes

- Methodology and survey procedures (i.e., dwell times and viewing angle) to ensure all regulated components are monitored

- A plan for avoiding camera operator fatigue

- A procedure for documenting fugitive emissions or leaks

Daily Verification Check

The OGI operator must perform a daily verification check and also record a 5-to-10-second video confirming the camera is operating properly. Verification check requirements are standard camera start-up procedures to confirm the camera is functioning properly. A butane lighter or propane cylinder can be used to fulfill this requirement.

Once a day, each operator must record a quality assurance (QA) verification video that is a minimum of 5 minutes long. The video must document the procedures the operator uses to survey (e.g., dwell times, angles, distances, backgrounds) and the camera configuration. As a time-saving method, operators could capture this video as part of the daily verification check.

Field Conditions Within Established Operating Envelopes

The OGI operator will need to have procedures for monitoring weather conditions every hour while on-site to make sure they remain within established operating envelopes. This will require each operator to have a meteorological station that meets the requirements outlined in the proposed Appendix K protocol. The ability of an operator to visualize a leak is dependent upon several different interferences and adverse monitoring conditions, including wind, poor delta-T, steam, fog, mist, rain, solar glint, extremely high concentrations of particulate matter, and hot temperature backgrounds. For example, high wind can disperse vapor clouds, potentially making it more difficult to view gas releases from leaking equipment. If any of these conditions are outside the allowable thresholds defined in the operating envelope, the viewing distance will need to decrease, or the survey may need to be delayed. The maximum viewing distance each day must be determined and documented.

Methodology and Survey Procedures

Sites must conduct monitoring surveys using one of three approaches that ensure all regulated components are appropriately monitored. These include:

- Use of a route map or a map with designated observation locations

- Use of visual cues (e.g., tags, streamers, or color-coded pipes)

- Use of global positioning system (GPS) route tracing

Each of the proposed approaches has complications such as updates for new process equipment and variable site conditions. These approaches will need to be adjusted over time to keep up-to-date with regular quality assurance and quality control (QA/QC). GPS route tracing is the most advanced approach but could be challenging to implement due to device location accuracy and battery life concerns. Notably, under the proposed changes, the use of a component database alone is not a substitute for the approaches in the protocol.

In addition to documenting the regulated equipment is appropriately monitored, the site will have to develop a procedure that describes how components will be viewed with the OGI camera. In general, the following proposed requirements apply to surveying components:

- Components should be surveyed from at least two different angles

- The operator must dwell on each angle for a minimum of 5 seconds before changing the angle, distance, or focus and dwelling again

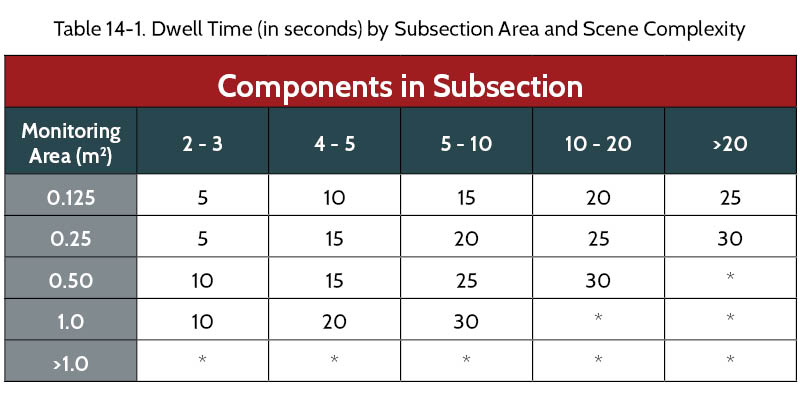

- The operator may reduce the dwell time for complex scenes based on the monitoring area and the number of components in a subsection as prescribed in Table 14-1 of Appendix K, provided the manageable subsection for the angle fills greater than half of the field of view of the camera

Camera Operator Fatigue

For the first time in a method, camera operator fatigue is addressed. Appendix K cites physical, mental, and eye fatigue as concerns with the continuous field operation of OGI cameras. Operators will be required to take 5-minute breaks for every 20 minutes of surveying. This means 20% of available survey time will now be devoted to breaks (2 hours/8-hour day).

Although some breaks can coincide with existing pauses in monitoring or breaks (such as for meals), this significantly increases the time on-site, resulting in less survey time or fewer surveys completed. As a substitute, two OGI operators can alternate time on the camera if continuous surveying is required, which may be a more viable option for larger facilities where mobilization time between facilities is not a factor. An increase of time on-site or decrease in the number of facility surveys completed in a day comes at an increase in program cost.

As proposed, the time investment for conducting surveys is substantial, and will likely lead to considerable cost increases to complete OGI surveys. These costs have the potential to directly impact program budgets and require considerable additional resources. Our upcoming final article of the series on Appendix K will discuss these challenges and how to manage the significant recordkeeping requirements in the proposed protocol.

Comment Period Extended

On December 13, 2021, EPA extended the comment period for the proposed rule, moving the comment deadline from January 14, 2022, to January 31, 2022.

Questions? Contact us!