Until now, only facilities storing specific amounts of oil near sensitive environments needed Facility Response Plans (FRPs) alongside Spill Prevention, Control, and Countermeasure (SPCC) Plans. In a recent regulatory update, the Environmental Protection Agency (EPA) issued a final rule, Clean Water Act Hazardous Substance Facility Response Plans. This new rule expands the requirement for FRPs to include facilities handling certain hazardous substances exceeding established reporting thresholds. These facilities must now plan for potential worst-case discharges of these Clean Water Act (CWA) listed substances.

The Final Rule applies to land-based facilities where CWA hazardous substances are made, used, stored, or otherwise handled. Many sectors could be impacted, including manufacturing, chemicals, storage near navigable waters, and facilities with large inventories of these hazardous substances. This could include facilities related to oil and gas, mining, construction, utilities, agriculture (crop and animal production), aquaculture, and support activities for agriculture and forestry.

The new regulations for hazardous substances may also affect facilities within a half-mile radius of navigable waters or conveyance systems already subject to SPCC or FRP requirements for oil under 40 CFR Part 112. Existing rules already regulate FRPs for oil facilities.

The rule takes effect on May 28th, 2024, with a 36-month grace period for implementation.

Clean Water Act Hazardous Substance Facility Response Plan Applicability

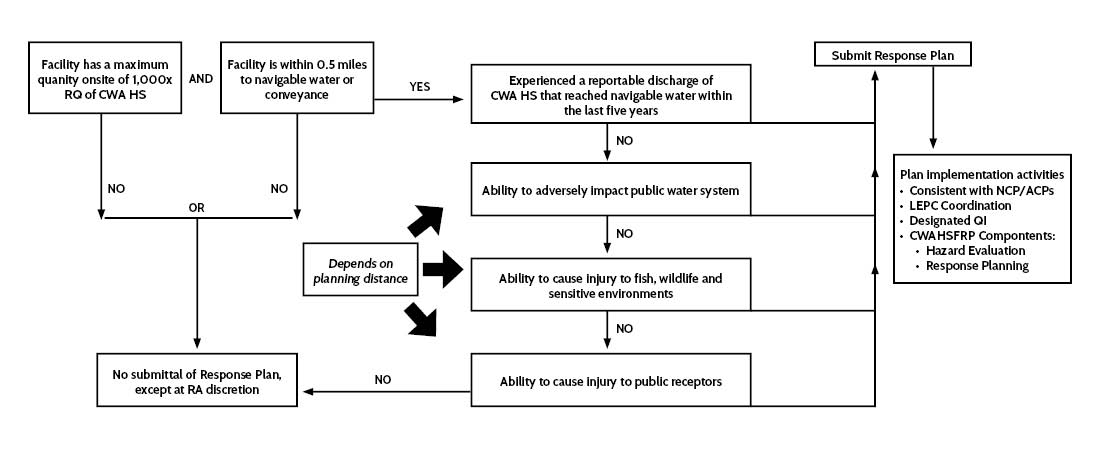

Under the new regulation, the EPA established a two-step process in 40 CFR 118.3 to determine if a facility needs a hazardous substance FRP.

Step 1: Initial Screening

Facilities must conduct an initial screening to see if they meet either of these criteria:

Does the facility store Clean Water Act (CWA) listed hazardous substances exceeding 1,000 times their Reportable Quantity (RQ)? Refer to 40 CFR Part 117 (Table 117.3) for specific RQs. For convenience, the table contains a column headed “Category,” which lists the code letters “X,” “A,” “B,” “C,” and “D” associated with reportable quantities of 1, 10, 100, 1000, and 5000 pounds, respectively.

To assess environmental risk, the rule considers the total volume of hazardous substances exceeding their Reportable Quantities (RQs) rather than just the size of the containers storing them.

If a facility meets EITHER of these criteria (with no implied priority), they proceed to Step 2.

Step 2: Substantial Harm Evaluation

Facilities that meet the initial screening criteria need to assess if they pose "substantial harm" based on four factors:

Ability to adversely impact public water system.

Ability to cause injury to fish, wildlife, and sensitive environments.

Ability to cause injury to public receptors.

Has experienced a reportable discharge of CWA hazardous substances that reached navigable water within the last five years.

It is important to note that the initial screening criteria for the new hazardous substance FRP are similar to those used for the existing oil FRP process, which preexisted the rule. This means facilities that already require an oil FRP may likely need a hazardous substance FRP as well.

Required Actions for Facilities Meeting Screen and Substantial Harm Criteria

Facilities that meet the initial screening criteria AND at least one of the substantial harm criteria must take action:

The owner or operator must prepare and submit an FRP to the EPA. This FRP must include details on each CWA hazardous substance stored on-site in quantities exceeding the threshold amount.

The owner or operator must assess all four substantial harm criteria to determine the full range of environmental and public health risks.

The FRP needs to address each CWA hazardous substance above the threshold, not just the one triggering substantial harm. Response and recovery actions can differ significantly depending on the specific substance released.

Similar to the oil FRP requirements, the rule mandates reviewing and recertifying the FRP every five years to ensure its effectiveness.

Facility owners or operators must evaluate or reevaluate their FRP whenever the EPA updates the list of CWA hazardous substances (40 CFR 116.4) or adjusts the RQs found in 40 CFR 117.3. This ensures the FRP remains current with regulatory changes, a requirement different from the oil rule.

Clean Water Act Hazardous Substance Facility Response Plan Schedule

Facilities subject to the rule must develop, submit, and implement their FRPs according to the following schedule:

Initially regulated facilities (operating by November 30, 2026) must implement the new requirements by June 1, 2027. This applies to existing facilities that meet the criteria on that date.

Newly regulated facilities (starting operation after November 30, 2026) must comply within six months of starting operation.

Newly constructed facilities (operating after June 1, 2027) must comply before starting operations, with a 60-day grace period for adjustments during the initial startup phase.

Curious if the Clean Water Act Hazardous Substance Facility Response Plan affects you? We Can Help.

Trihydro’s regulatory specialists stay current on changing regulations to support you in maintaining compliant operations and reporting. Contact us to discuss how the Clean Water Act Hazardous Substance Facility Response Plan affects your facility.